info@amethystresearch.net

Services

We specialize in

FULLY CUSTOMIZED INFRARED SOLUTIONS, starting with

epitaxial structure design and ending with device prototyping

and small-volume manufacturing.

Because, like you, we have commercialization in mind, we

choose solutions that combine ultra-high performance,

cost-effectiveness, and fast development-to-prototype cycle

times.

Whether you are developing a DoD mission-critical system (or

managing sensor innovation for your agency), looking for a

cutting-edge device for your commercial infrared system, or

looking to transfer your ideas out of your research

institution’s lab, we welcome an opportunity to support your

needs.

Custom Design and Fabrication of

Infrared Photodetectors and

Emitters

Device Design/IP

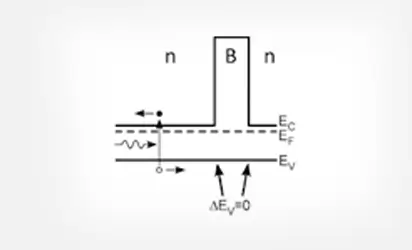

Based on your specifications, such as wavelength range, sensitivity, response time, & the application, our team proposes a detector design (RCE-PDs, APDs, nBn, LEDs or other) & semiconductor materials of choice for the substrate & III-V epilayers.

Semiconductor Growth

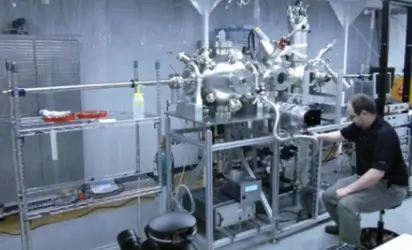

After the design is established, we grow the III-V epitaxial layers using Molecular Beam Epitaxy (Riber R&D reactor).

Materials Characterization

Growth is followed by materials analysis to ensure the quality of the III-V layers prior to the fabrication of the device.

Passivation Technologies

Our proprietary hydrogenation process, undertaken post-growth, improves the epi-wafer quality further by reducing the number of defects that impact electronic properties.

Fabrication & Evaluation

With access to a microelectronics center, we use microfabrication techniques (lithography, etching, doping and contact formation) to make arrays of trial devices. We examine the devices (optical, SEM) and test their opto-electronic properties in an environment suitable for the stage of development.

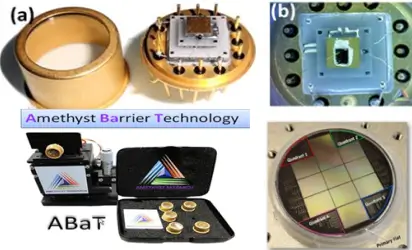

Prototype Packaging

We integrate the prototype devices into standard packages in an inert environment and optionally with a thermoelectric cooler. Typically, we include a trans-impedance amplifier that converts photocurrent to voltage.

Technology Readiness Levels (TRL) from 1 through 6 are addressed entirely with internal capabilities and our established supply chain. Higher TRL’s can be addressed with integration partners.

How Our Capabilities Tie Together

Device Design

Based on your requirements, (wavelength range, sensitivity, response time and other), and selected application, we formulate a detector design within the suite of detector types we develop internally or with our university partners. We have extensive experience in nBn, RCE-PD, APD, SPAD, LED architectures and more.

MBE Growth Of III-V Epilayers

Our focus is on quality. We ensure the best performance and operability of our III-V photodetectors and photoemitters by using our Riber research MBE reactor in conjunction with our proprietary hydrogen passivation process, a technique particularly well suited for compound semiconductors. The scale and flexibility of our MBE growth allows affordability (i.e. for Phase 1 exploratory work). Our specialty is antimonides, arsenides, and dilute phosphides and nitrides.

Materials Characterization

Materials characterization techniques include FTIR-based optical reflection and transmission, Hall Effect, XPS, RBS, NRA, ERDA, PIXE, AFM, XRD and RAMAN. These tools are used to support MBE but can also be used for wafers or materials provided by clients/research partners.Ion beam methods are especially useful for studying point defects and hydrogen incorporation to mitigate defects.

Prototyping

Excellent university-based microelectronics facilities (UT-Austin and Lancaster University) support the fabrication of devices ranging from 25 to 1,000 microns in size and covering the suite of detector types and materials families. Evaluation includes microscopies, spectral response, dark current analysis, sensitivity, detectivity, and quantum efficiency. Packaging processes comprise dicing, thermal bonding, wire-bonding, and sealing. Wavelength and operating temperature determine the materials used.